Segments Vertical Surface Crusher Machines

.jpg)

How it Works: Crushers, Grinding Mills and

2017年6月2日 Vertical shaft mills work on the same principal as VSI crusher, with a rotor on a vertically mounted shaft using centrifugal force to throw the media against a wear plate High pressure grinding rollers (HPGR) , also 2020年4月14日 VERTICAL SHAFT IMPACT CRUSHERS (VSI) TECHNICAL SPECIFICATION CV200 RANGE VSI CRUSHER OPERATIONAL FLEXIBILITY Sandvik Stationary VSI SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT 2023年9月14日 VERTICAL SHAFT IMPACT CRUSHER RETROFITTING Upgrading with a Top Half Retrofit reduces power consumption, increases crusher throughput, requires fewer wear CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS2019年9月10日 CRUSHER SERIES Sandvik CG800i crushers are built to be robust, reliable and efficient Connected to My Sandvik, they revolutionize availability and optimize uptime by SANDVIK CG800i GYRATORY CRUSHER SERIES Sandvik

.jpg)

Development and testing of a novel mathematicalphysical model for

2021年8月15日 Vertical shaft impact crusher (VSI) is amongst the most utilized comminution machines in the aggregate industries because of it is capacity to produce a large amount of The Trio® TV Series vertical shaft impact crusher is a highperformance comminution machine, best suited for fine crushing applications and the creation of highquality end productsTrio® TV Series Vertical Shaft Impact (VSI) Crushers Weir2024年10月16日 Advantages 01 Hydraulic Lid Lifter Provide quick access for routine inspections and quick and easy maintenance 02 Interchangeable chambers Accommodates several rotor and anvil configurations for Cemco® Vertical Shaft Impactor (VSI) Superior 2008年8月1日 The vertical shaft impact (VSI) crusher is a commonlyused machine in aggregate production A comprehensive understanding of the physical phenomena that influence the Modelling of output and power consumption in vertical shaft impact

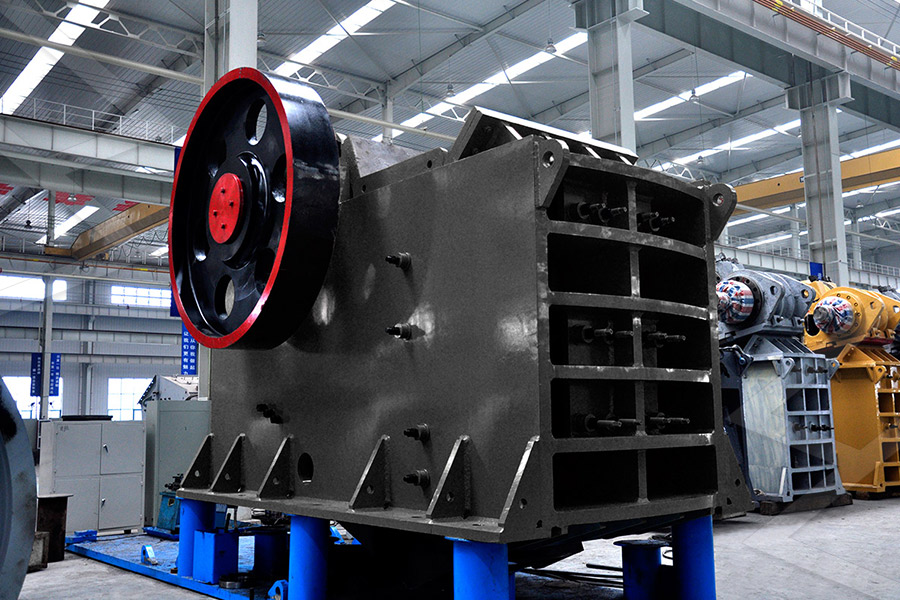

Vertical Shaft Impact Crusher machinerylinefo

2022年8月29日 Kinglink KLSeries Vertical Shaft Impact Crusher offers the modern operating product grading control by optimising numerous variables: • Variation of rotor speed • Choice 2020年5月30日 The Nederman vertical metal chip crusher type KB accepts, crushes and breaks up bushy swarf, turnings and metal chips and at a low rotating speed the bushy swarf is cut Vertical metal crusher, type KB, for chips, swarf and 2023年2月28日 The primary crusher’s function is to reduce the size of the rock or stone for easier handling and transportation The primary crusher is usually a jaw crusher or a gyratory crusher, which operates by compressing the material Primary Crusher vs Secondary Crusher: 2020年5月30日 The crusher is intended for carbon steel, stainless steel and other alloyed steel with tensile strength up to 1200 N/mm2 (174,000 psi), aluminium alloys, sponge iron and titanium Technical description of vertical chip crusher The Nederman vertical metal chip crusher type KB accepts, crushesVertical metal crusher, type KB, for chips, swarf and

.jpg)

polysius® crusher thyssenkrupp Polysius

To do this, the entire upper part of the crusher had to be dismantled in advance, which was timeconsuming and costly The crusher segment design from thyssenkrupp Polysius now makes it easy to replace the crusher segments 2023年2月22日 Vertical Shaft Impact Crusher: A vertical shaft impact crusher uses a vertical shaft to crush materials It is commonly used in mining, recycling, and construction Stationary Impact Crusher: A stationary impact crusher is designed to be fixed in one location It is commonly used in mining and constructionDifferent Types of Stone Crusher Machines AGICOThe NV series of Reciprocating Surface Grinders with Vertical Spindle is optimized for precise and efficient flat grinding of a variety of materials This series is very versatile and can be tailored to meet a wide range of grinding options from light flat grinding to high material removal rates with high horse power spindle optionsRobust Vertical Spindle Reciprocating Surface Grinders Alex Machine Special to the strikebar crusher are the interchangeable, segmented strike bars, designed to increase wear life significantly Each segment can be easily interchanged, rotated and repositioned Interchanging between four different positions makes each strike bar usable for up to 50 percent of its original weight, which is a significant savingStrikeBar™ Crusher FLSmidth Cement

.jpg)

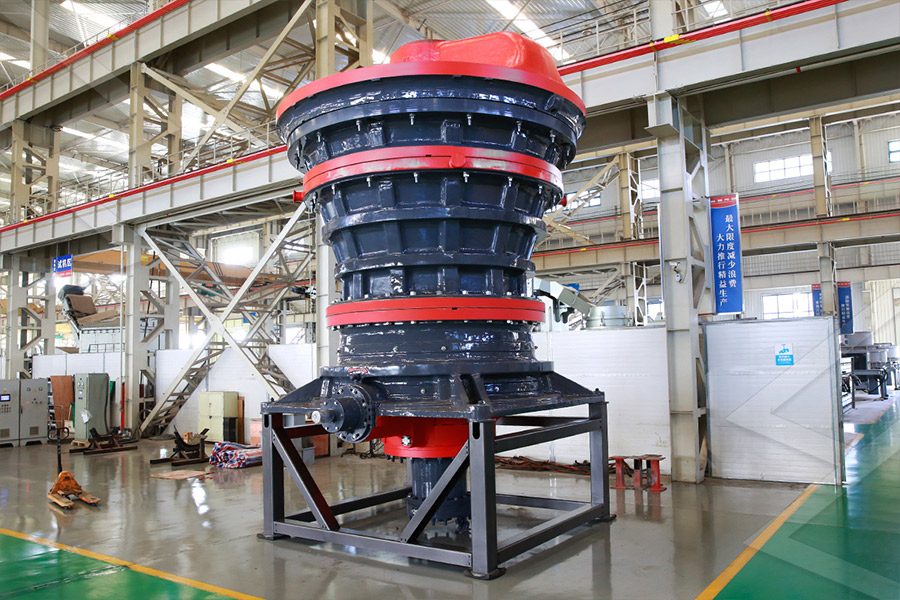

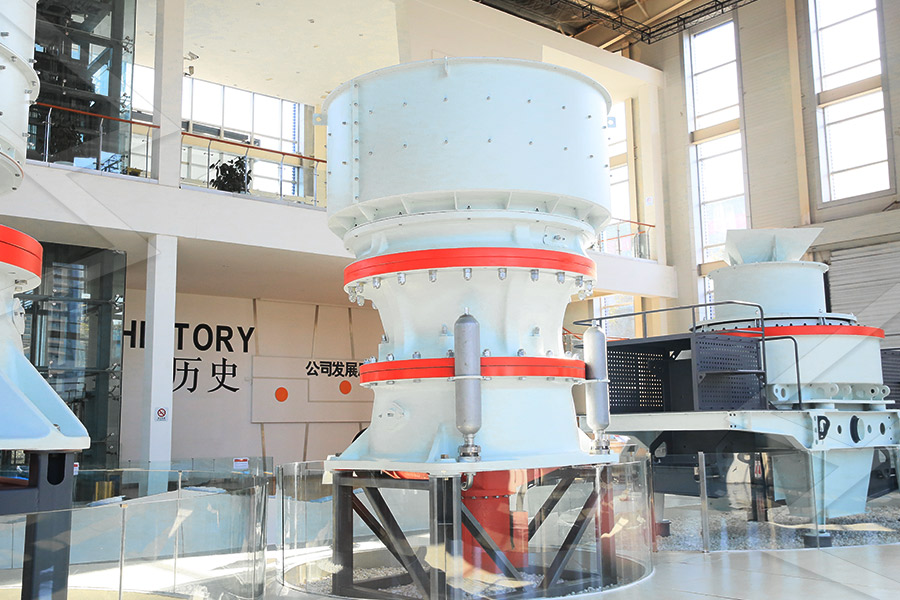

Gyratory Crusher Parts Casteel Foundry

A gyratory crusher mantle or a set of concave segments with a longer wear life do not need to be replaced as often You will need fewer per year but also have fewer maintenance shutdowns is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel 2023年2月18日 Gyratory crusher wear parts include mantles, concave segments, and spider caps Mantles are the main wearing component and come in different designs to suit different crushing applications Concave segments cover the entire surface of the concave and come in different profiles to suit different types of crushing applicationsCrusher Wear Parts: What They Are and Why They MatterThe Donasonic CROSSFLOW Vertical Crusher is designed with robust simplicity in mind The CROSSFLOW is a highpower homogenisation machine, capable of processing difficult materials with speed, reliability and efficiency High throughputs of up to 5 TPH for the smaller x95, and up to 14 TPH for the larger sized machineCROSSFLOW Vertical Crusher / X95 125 165 205 255 Crushing MachinesAll You Need to Know About: Vertical Shaft Impactor (VSI) Primers By Eric Marcotte, Inside Sales Manager, Stedman Machine Company Vertical Shaft Impactor What Is VSI? All roads, you might say, lead to the Vertical Shaft Impactor (VSI) because these crushers make it possible to create roadways and just about everything else Francis E Agnew of California patented one of the All You Need to Know About: Vertical Shaft Impactor (VSI)

« DESIGN OF A STONES CRUSHER MACHINE» rufso

2022年4月11日 CRUSHER MACHINE» Review University without Border for the Open Society (RUFSO) ISSN: 2313285X Volume: 32, Issue: 01, April 2022 crushing surface • Double Roll Crusher Review University without Border for the Open Society (RUFSO) ISSN: 2313285X Volume: 32, Issue: 01, April 2022 crusher and vertical shaft impact stone crusher based 1994年7月1日 1 Introduction In vertical surface grinding, wheel segments (eight or more, depending upon the wheel diameter) are used generally instead of a continuous wheel These segments, after having been clamped onto the wheel hub, are treated usually with the help of a serrated type of wheel crusher made of hard steelMechanics of vertical surface grinding ScienceDirectThe walls of the gyratory crusher’s hopper are lined with “Vshaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone The ore is discharged through the smaller bottom output hole of the cone While the cone Types of Crushers: What You Need to Know2023年2月28日 Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages, disadvantages, applications, and factors to consider when selecting them Discover case studies and examples of successful applications, as well as future developments in secondary crusher A Comprehensive Guide to Secondary Crusher Types AGICO

Profimach PGSRVSeries Vertical Rotary Table Surface Grinding Machines

Vertical Rotary table Surface Grinders High Efficient Vertical Rotary Table Surface Grinding Machines Vertical Rotary Grinders provide high efficiency compared to conventional surface grinders due to the significant amount of grinding wheel in Discover Alex's RV Series Vertical Spindle Rotary Grinders for peak production and precision Durable for demanding tasks, our range ensures optimal grinding This family of Alex machines are used for surface grinding where maximum production, finish and accuracies are prerequisites Segment Wheel Diameter mm (in) 350 (14) 450 (18) 550 RV Series Rotary Surface Grinder Alex Machine ToolsIn a tough environment, you need robust equipment that won’t let you down The Double Roller Crusher is a heavyduty machine designed to withstand the rigours of the mining industry With high capacities and minimum downtime, this rolling crusher is ideal for both soft and mediumhard rock crushing applicationsDouble Roll Crusher DRC FLSmidth5 天之前 The gyratory crusher consists of a coneshaped crushing head mounted on a vertical shaft The vertical shaft hangs from the top of the crusher and is supported by a spider FTM Machinery has upgraded gyratory crusher spares many times and finally designed a large crushing chamber, highstrength main shaft, adjustable main shaft positioning Gyratory Crusher Fote Machinery

.jpg)

Vertical spindle surface grinding of AISI 1020 and A36 steels

2016年4月15日 The studies described in this paper focus on the wear behavior of duplex grade abrasive segments grinding AISI 1020 and A36 steels on a vertical spindle surface grinding machine (VSSG) The study focuses on the behavior of the abrasive segment and how it contributes to significant changes in the grinding ratio and the type of wear that is occurring Our expertise in mining equipment and industrial machinery has led us to develop exactly such solution with our innovative and unique hard rock crusher, the Eccentric Roll Crusher ERC® This highly wear resistant, highly durable machine offers a significant efficiency boost for mining operations, thanks to its particularly flat and robust Eccentric Roll Crusher ERC® FLSmidthFind here Vertical Shaft Impact Crusher, Vertical Crusher manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Vertical Shaft Impact Crusher, Vertical Crusher Vertical Shaft Impact Crusher Vertical Crusher Vertical shaft impact (VSI) crusher machine exporters, manufacturers in Mumbai, India VSI crusher machine from Rocktech Engineers is the perfect solution for your needs Rocktech Engineers: Leading Industrial Company in Asia +91 Vertical Shaft Impact (VSI) Crusher Machine

Efficient RA Series Rotary Surface Grinder Alex

Robust Grinding Capability: The RA Series stands strong with a vertical spindle that cuts down on cycle times, enabling efficient singlepass grinding Adaptable to Your Needs: This series is engineered to handle a diverse array of small 2012年11月8日 Crusher Jaws Grinding Rolls And Bull Ring Segments 1BHEL Coal Mill Spares 2Grinding Rolls Bull Ring Segments for BHEL Coal Mills 3BHEL Boiler Spares function of dam ring in vertical roller millsRoller Mill Grinding Rolls And Bull Ring Segments Crusher Any time the material or rock is used as an impact wear surface the term autogenous is used Putting a top on the rotor table and shoes allows autogenous use During operation of the VSI, a bed of material can be designed to build up inside the What Is A Vertical Shaft Impactor (VSI) Primer? Stedman MachineAn analytical model of slotless PM motor with segmented magnets is presented The Ampere's approach is adopted for the modeling of permanent magnets and separation variables method is used to calculate magnetic field in all magnetic airgap of the motor The model considers parallel magnetized magnet segments by the introduction of volume current densities inside the Analytical model of parallel magnetized magnet segments of surface

.jpg)

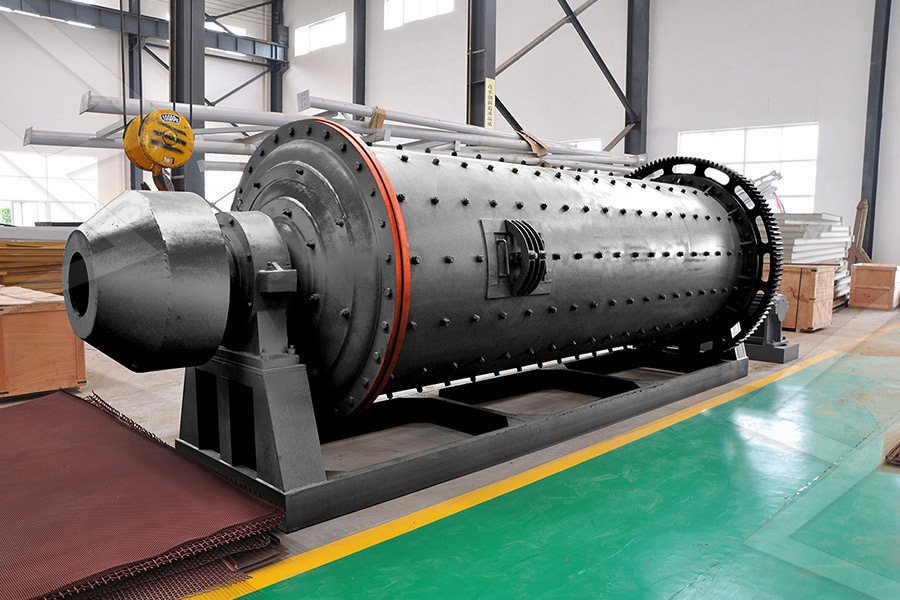

Modelling of output and power consumption in vertical shaft impact

2008年8月1日 The vertical shaft impact (VSI) crusher is a commonlyused machine in aggregate production A comprehensive understanding of the physical phenomena that influence the power consumption and the particle output of the device are essential to enable development of protocols that minimize energy consumption during rock crushing While natural gravel has Puzzolana India 9,665 followers on LinkedIn Leading innovation in crusher manufacturing since 1964 Puzzolana is a diversified group based out of Hyderabad with worldclass infrastructure in place Founded in 1964, Puzzolana has five decades of enviable experience and a reputation for delivering effective, economical environmentally compatible engineering solutions to Puzzolana India LinkedInWe are satisfied from the TFICO products since the served the crusher site for our company with STRONG AND WELL MANUFACTURED Machines, the Belt Conveyors and Jaw Crusher machines are perfect the Screen vibrators separates the stones nicely and the other components of the stone crusher machines are well producedStone (Beton) Crusher Production Lines – Industrial Machinethe rock crusher of the present invention comprises the following improvements directed to overcoming the aforementioned disadvantages of prior art machines: the impeller shoes have forwardly tapered faces located on their inner ends causing them to wear evenly; the impeller table liners are portioned into, first segments which are located under and forwardly adjacent USA Centrifugal impact rock crushers Google

.jpg)

Primary Crusher vs Secondary Crusher:

2023年2月28日 The primary crusher’s function is to reduce the size of the rock or stone for easier handling and transportation The primary crusher is usually a jaw crusher or a gyratory crusher, which operates by compressing the material 2020年5月30日 The crusher is intended for carbon steel, stainless steel and other alloyed steel with tensile strength up to 1200 N/mm2 (174,000 psi), aluminium alloys, sponge iron and titanium Technical description of vertical chip crusher The Nederman vertical metal chip crusher type KB accepts, crushesVertical metal crusher, type KB, for chips, swarf and To do this, the entire upper part of the crusher had to be dismantled in advance, which was timeconsuming and costly The crusher segment design from thyssenkrupp Polysius now makes it easy to replace the crusher segments polysius® crusher thyssenkrupp Polysius 2023年2月22日 Vertical Shaft Impact Crusher: A vertical shaft impact crusher uses a vertical shaft to crush materials It is commonly used in mining, recycling, and construction Stationary Impact Crusher: A stationary impact crusher is designed to be fixed in one location It is commonly used in mining and constructionDifferent Types of Stone Crusher Machines AGICO

Robust Vertical Spindle Reciprocating Surface Grinders Alex Machine

The NV series of Reciprocating Surface Grinders with Vertical Spindle is optimized for precise and efficient flat grinding of a variety of materials This series is very versatile and can be tailored to meet a wide range of grinding options from light flat grinding to high material removal rates with high horse power spindle optionsSpecial to the strikebar crusher are the interchangeable, segmented strike bars, designed to increase wear life significantly Each segment can be easily interchanged, rotated and repositioned Interchanging between four different positions makes each strike bar usable for up to 50 percent of its original weight, which is a significant savingStrikeBar™ Crusher FLSmidth CementA gyratory crusher mantle or a set of concave segments with a longer wear life do not need to be replaced as often You will need fewer per year but also have fewer maintenance shutdowns is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel Gyratory Crusher Parts Casteel Foundry2023年2月18日 Gyratory crusher wear parts include mantles, concave segments, and spider caps Mantles are the main wearing component and come in different designs to suit different crushing applications Concave segments cover the entire surface of the concave and come in different profiles to suit different types of crushing applicationsCrusher Wear Parts: What They Are and Why They Matter

.jpg)

CROSSFLOW Vertical Crusher / X95 125 165 205 255 Crushing Machines

The Donasonic CROSSFLOW Vertical Crusher is designed with robust simplicity in mind The CROSSFLOW is a highpower homogenisation machine, capable of processing difficult materials with speed, reliability and efficiency High throughputs of up to 5 TPH for the smaller x95, and up to 14 TPH for the larger sized machineAll You Need to Know About: Vertical Shaft Impactor (VSI) Primers By Eric Marcotte, Inside Sales Manager, Stedman Machine Company Vertical Shaft Impactor What Is VSI? All roads, you might say, lead to the Vertical Shaft Impactor (VSI) because these crushers make it possible to create roadways and just about everything else Francis E Agnew of California patented one of the All You Need to Know About: Vertical Shaft Impactor (VSI)