Crushing And Grinding Processes In Belize

sbm/sbm crushing and grinding system in belizemd at main

Contribute to redmik40/sbm development by creating an account on GitHub2020年3月1日 Processed MWD data can be used to predict the rockbreakage efficiencies in crushing and grinding processes based on the relationship between drilling performance Use of drilling performance to improve rockbreakage Crushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is called WHAT IS THE CRUSHING PROCESS? MEKACrushing and grinding are mechanical processes used to reduce the size of materials, typically in the mining and mineral processing industries These processes help liberate valuable minerals Crushing and grinding (Mineralogy) Fiveable

Reduction of Fragment Size from Mining to Mineral

2022年10月4日 In general, crushing and grinding are together called comminution in mineral processing and grinding is typically the highest energy consuming stage of the mineral 2017年3月1日 Crushing and grinding marginally differ from the fact that crushing liberates particles in coarser size ranges whereas grinding in finer size ranges Grinding is deemed as Pretreatment of rocks prior to comminution ScienceDirectThe process of material pieces or grains reduction by destruction under the influence of external mechanical forces, depending on the size of the final product, is called crushing or grinding Reengineering of the ore preparation production 2017年8月25日 • Comminution, or crushing and grinding, to prepare the ore for the following separation steps • Physical separation, or mineral dressing, or beneficiation, to separate theCHAPTER 5 GENERAL PRINCIPLES OF MINERAL

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by 2003年1月1日 This paper examines the role blasting plays in optimum crushing and grinding with the emphasis on energy reduction The role of different blasting energy input on fragmentation is studied, andThe Effects of Blasting on Crushing and Grinding Mathematical modelling and automatic control of mineral crushing and grinding circuits have been studied at the Queensland Julius Kruttschnitt Mineral Research Centre for several years While much is still to be done, it is considered that knowledge of the subject has reached the point at which a useful monograph may be published The emphasis in this monograph is on the Mineral Crushing and Grinding Circuits Semantic Scholar2010年7月1日 Crushing and grinding processes have undergone significant changes over the last 20 years These adjustments have focused on lowering costs and increasing production and energy efficiency, mainly The Evolution of Crushing and Grinding: Changes in the Industry

Understanding the Difference Between Crushing Grinding

2024年6月26日 The material is subjected to grinding process in between two surfaces moving towards each other at varying speeds, thereby creating fine, even product Stages of Grinding Crushing occurs in stages, unlike grinding, which just has a beginning, middle, and end as per the desired fineness of the outputPreface Introduction Review of Process Development The Physics of Breakage Particle Shape, Size and Surface Classification Energy for Size Reduction Scaling of Capacity and Energy Basics of Mathematical Simulation Modelling of Tumbling Mill Batch Processes Simulation of Closed Circuits Specialised Methods of Size Reduction Appendices IndexCrushing and Grinding Process Handbook Semantic Scholar2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as Crushing and Grinding Process JXSC Machine2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separationCrushing Mineral Processing 911Metallurgist

.jpg)

Mineral processing Metallurgy, Crushing Grinding

Today, these processes are carried out in mechanized crushers and mills Whereas crushing is done mostly under dry conditions, grinding mills can be operated both dry and wet, with wet grinding being predominant Crushing Some ores occur in nature as mixtures of discrete mineral particles, such as gold in gravel beds and streams and diamonds 2016年2月29日 Basically, the amalgamation process comprises the following stages, crushing and grinding the ore until get a K80 of approximately 35 mesh Finer values work and the final particle size is dependent on the mineralogyGold Extraction Recovery Processes 911MetallurgistA summary of the underlying principles in the field of comminution that harmonises conflicting conclusions and sets down, in logical sequence, the most important research advances and mathematical models to date Draws from the vast literature in crushing and grinding studies, and points out the limitations of equations formulated in the past and the interrelationships of Crushing and Grinding Process Handbook Google Books2023年12月1日 Crushing is a dry process whereas grinding is generally performed wet and hence is more energy intensive Crushing is done using mechanical crushers There are several types of crushers available inSIZE REDUCTION BY CRUSHING METHODS By

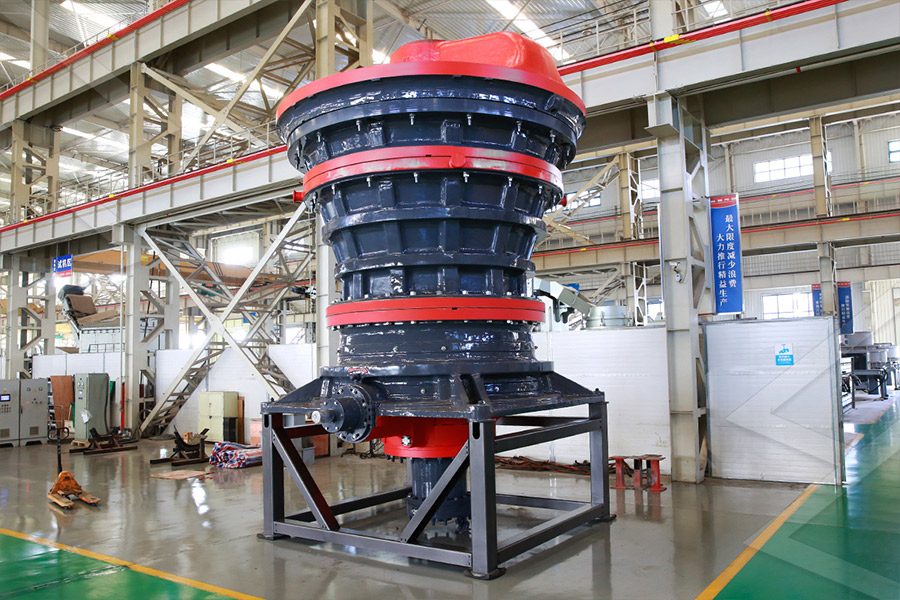

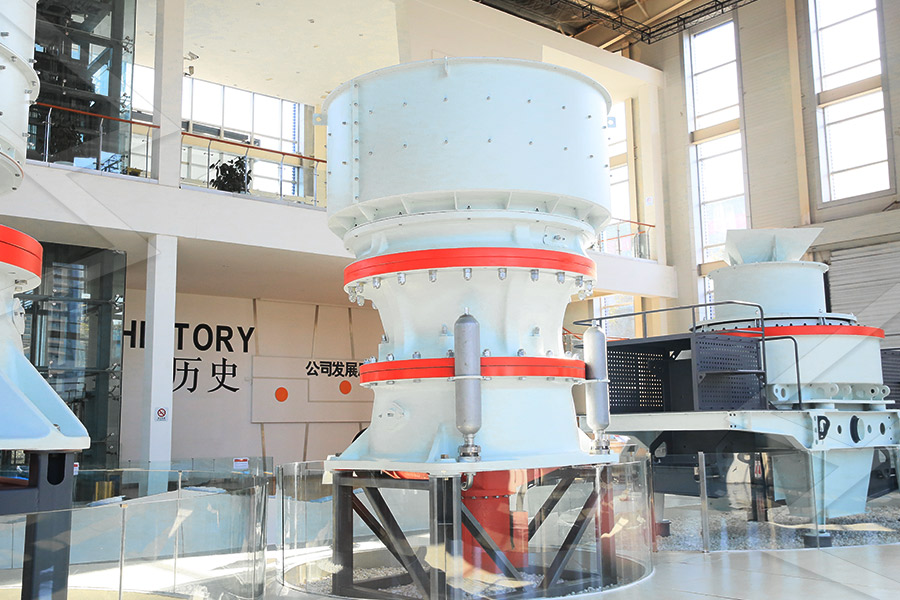

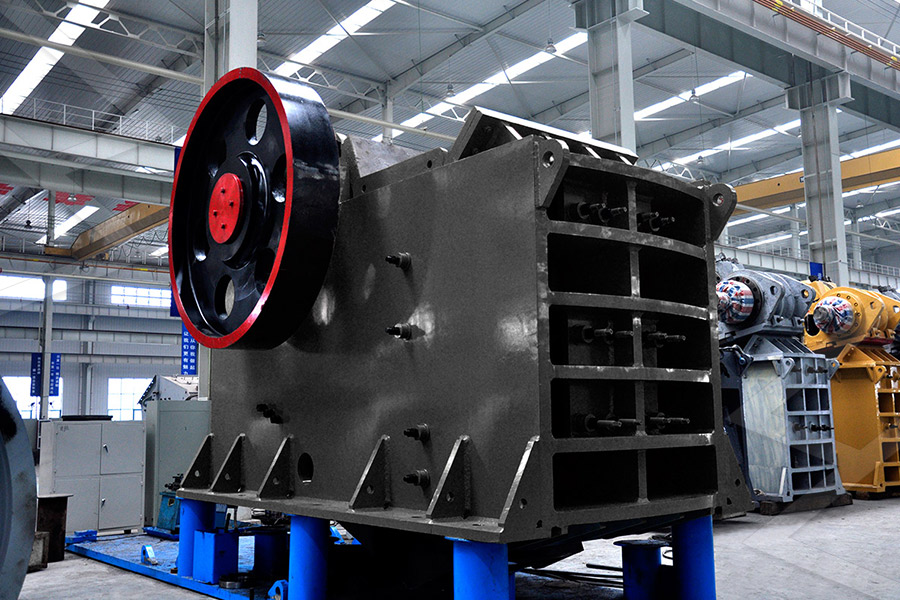

Ore Crushing SpringerLink

2023年7月22日 Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm The maximum crushing ratio of coarse crushing is about three The main force in the coarse crushing of ore is crushing Typical coarse crushing equipment includes jaw crusher, gyratory crusher, and rollertooth crusher Ore 2024年9月1日 Crushing and grinding operations are the basis of raw materials processing and can be characterized with very high energy consumption at relatively low breakage effectiveness In general, there can be found 388 papers in ENERGY Journal, that contribute to the grinding process, and 31 publications relating to comminution/crushing issues Impact of HPGR operational pressing force and material 2024年2月23日 The grinding process helps separate the good minerals from the useless parts and makes sure the next steps, like separating the minerals, work even better By following steps like crushing, grinding, screening, Mineral Processing: An InDepth Guide JXSC2003年1月1日 The impact of dynamic forces in rockblast fragmentation process has been the subject of investigation for years Nevertheless, while the influence of the macrofragmentation in downstream The Effects of Blasting on Crushing and Grinding

Dolomite Crushing Process And Grinding Equipment

2024年3月12日 The ultrafine grinding machine for dolomite powder has comprehensive mechanical crushing performance such as roller pressing, grinding, and crushing The equipment can form an independent and complete production system with strong systematicity, from the crushing, conveying, and powdermaking to the collection, storage, and packaging of 2024年9月1日 The paper concerns investigations on potential energy savings and breakage effectiveness, resulting from the application of HPGR device into ore mineral processing circuit A series of laboratory experiments in HPGR for sulphide copper ore was carried out at four values of pressing force in the press and four levels of moisture of the feed material (according to Impact of HPGR operational pressing force and material 2024年6月28日 Sampling errors Systematic bias in the process of taking an image can introduce serious errors Generally the size distribution of ROM fragmentation is obtained from the images of blasted muckpilesMODELLING FINES IN BLAST FRAGMENTATION AND ITS 2022年1月23日 To process the bauxite, the bauxite must be mined, crushed, and delivered to the refinery The first step to reaching the refinery after mining the bauxite is crushing The crushing circuit is defined by a series of variables and how those variables come together to affect each other Those variables include the following:Physical Bauxite Processing: Crushing and Grinding of

Overview of the soybean process in the crushing industry

1 Desmet Ballestra, Buenos Aires, Argentina 2 Desmet Ballestra, Zaventem, Belgium * Correspondence: vgibon@desmetballestra Received: 11 February 2020 Accepted: 7 September 2020 Abstract A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better revenue for the 2024年1月28日 Comminution refers to the process of reducing the size of solid materials through mechanical means The principles of comminution are guided by fundamental concepts in crushing and grinding operations: Crushing and Grinding Forces: Comminution involves the application of forces, such as compression, impact, and attrition, to break down larger 32 Principles of comminuting Crushing and Grinding 2024年1月1日 Ball grinding process is a grinding method of crushing ore with ballshaped grinding medium in the grinding mill In the ball grinding process, because the steel ball has 360° free rotation, it is suitable for falling motion and throwing motion When the rotating speed of the cylinder is low, the medium rises to a certain height along the Ball Grinding Process SpringerLink2023年3月6日 As experience shows, when one determines the energypower parameters of crushing and grinding processes by using the existing methods, the power of motors used in drives of existing crushers of various types often turns out to be excessive [10, 11]In this case, the drive will operate at a relatively low load (ratio of the power consumed by the working body Study of the EnergyPower Parameters of the Crushing Process

MeasurementControl for Crushing and Screening Process

2023年6月3日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for 2023年12月18日 The two primary methods are crushing and grinding a Crushing: Crushing initiates the comminution process by breaking down large rocks or chunks into smaller, more manageable particles Primary Comminution in Mineral Processing: Breaking Down the Finding suppliers of mining crushers, breakers and grinding mills Crushers, breakers and grinding mills come in several different types Mining Technology has listed some of the leading suppliers of processing equipment in the mining drills and breakers market, based on its intel, insights and decades of experience in the sector The list includes suppliers of crushers, rock breaker Mining Crushers, Breakers Grinding Mills for the Mining 2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision It is widely used in the machinery manufacturing industry The heattreated and quenched carbon tool steel and carburized and quenched steel parts often have a large number of regularly arranged grinding cracks on the surface that is basically What is Grinding Process How It Works Different Types

36.jpg)

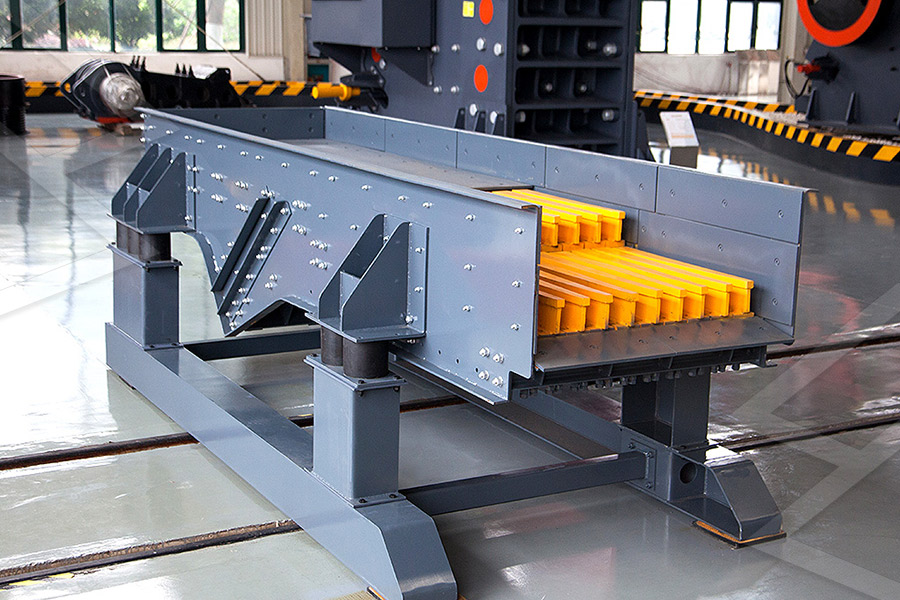

Crushing and grinding GTK

Crushing and grinding is one of the most demanding mineral technology processes because selection of the correct crushing and grinding process guarantees a successful separation process The investment and operation costs constitute a major part of the total beneficiation costs, and thus studying this subprocess during process design is 2023年2月28日 Primary crushing is different from other comminution processes, such as grinding, in that it breaks down the material using mechanical force, rather than by using friction or impact Unlike grinding, which produces a fine powder, primary crushing produces larger pieces of material, which are then further broken down by the secondary and The Complete Guide to Primary Crushing, Secondary Crushing2020年1月1日 The largest soybean crushing plant in the world with a capacity of 33 000 MTPD (22 000 MTPD in a single plant and 11 000 MTPD in a parallel line)Overview of the soybean process in the crushing industryThe Crushing And Grinding Machine is a standout piece in our Stone Crusher collectionChecking customer reviews, verifying certifications, and visiting the supplier's production facilities are essential steps in evaluating the quality and reputation of a stone crusher supplier Here we are going to show you some of the process equipments Crushing And Grinding Machine MadeinChina

.jpg)

Mineral Crushing and Grinding Circuits Semantic Scholar

Mathematical modelling and automatic control of mineral crushing and grinding circuits have been studied at the Queensland Julius Kruttschnitt Mineral Research Centre for several years While much is still to be done, it is considered that knowledge of the subject has reached the point at which a useful monograph may be published The emphasis in this monograph is on the 2010年7月1日 Crushing and grinding processes have undergone significant changes over the last 20 years These adjustments have focused on lowering costs and increasing production and energy efficiency, mainly The Evolution of Crushing and Grinding: Changes in the Industry 2024年6月26日 The material is subjected to grinding process in between two surfaces moving towards each other at varying speeds, thereby creating fine, even product Stages of Grinding Crushing occurs in stages, unlike grinding, which just has a beginning, middle, and end as per the desired fineness of the outputUnderstanding the Difference Between Crushing Grinding Preface Introduction Review of Process Development The Physics of Breakage Particle Shape, Size and Surface Classification Energy for Size Reduction Scaling of Capacity and Energy Basics of Mathematical Simulation Modelling of Tumbling Mill Batch Processes Simulation of Closed Circuits Specialised Methods of Size Reduction Appendices IndexCrushing and Grinding Process Handbook Semantic Scholar

.jpg)

Crushing and Grinding Process JXSC Machine

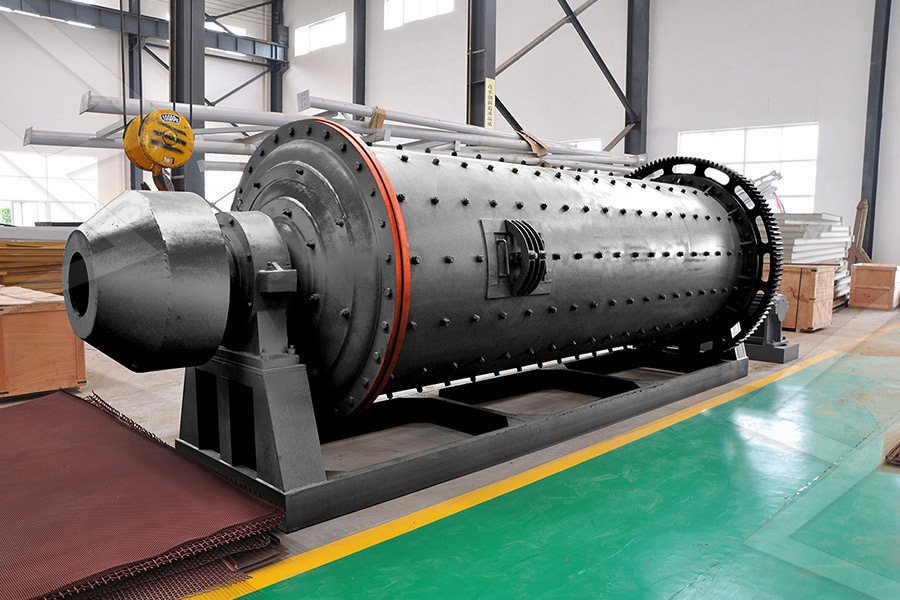

2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as 2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separationCrushing Mineral Processing 911MetallurgistToday, these processes are carried out in mechanized crushers and mills Whereas crushing is done mostly under dry conditions, grinding mills can be operated both dry and wet, with wet grinding being predominant Crushing Some ores occur in nature as mixtures of discrete mineral particles, such as gold in gravel beds and streams and diamonds Mineral processing Metallurgy, Crushing Grinding2016年2月29日 Basically, the amalgamation process comprises the following stages, crushing and grinding the ore until get a K80 of approximately 35 mesh Finer values work and the final particle size is dependent on the mineralogyGold Extraction Recovery Processes 911Metallurgist

.jpg)

Crushing and Grinding Process Handbook Google Books

A summary of the underlying principles in the field of comminution that harmonises conflicting conclusions and sets down, in logical sequence, the most important research advances and mathematical models to date Draws from the vast literature in crushing and grinding studies, and points out the limitations of equations formulated in the past and the interrelationships of 2023年12月1日 Crushing is a dry process whereas grinding is generally performed wet and hence is more energy intensive Crushing is done using mechanical crushers There are several types of crushers available inSIZE REDUCTION BY CRUSHING METHODS By